Sustaınable Productıon Wıthout Compromısıng Qualıty

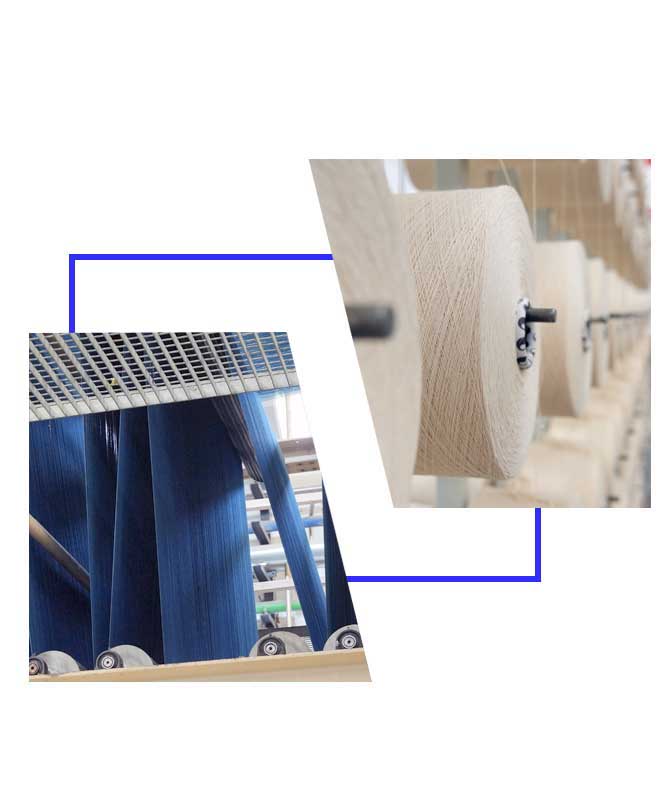

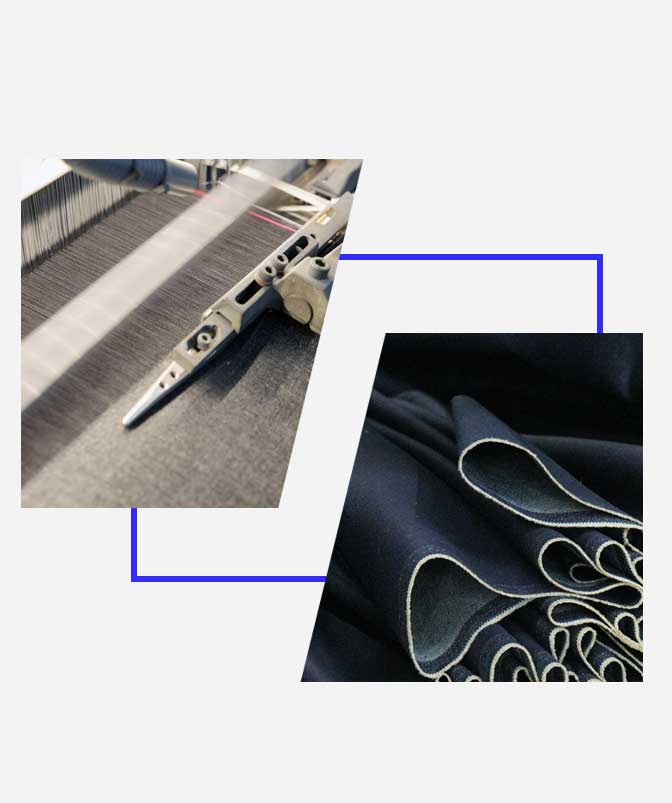

< class="paragraph">Rimsa Tekstil’s production philosophy is based on the principles of quality, innovation, and sustainability. Cotton, harvested directly from the fields, is processed using advanced technology to create high-quality yarn. This yarn is then transformed into denim fabric through state-of-the-art weaving machines. At every stage of production, we adopt the latest technologies to ensure an eco-friendly and sustainable process.

Rimsa aims to minimize its environmental footprint by adopting production methods that reduce carbon emissions and utilizing recyclable materials. With water-saving techniques, innovative dyeing methods that reduce chemical usage, and energy-efficient technologies, we provide environmentally friendly products to our customers.